In a new paper in the Journal of the American Chemical Society, Allen Bard and co-workers describe a new approach to create catalytic platinum structures the size of one to a few atoms fabricated on an atom-by-atom basis.

As electronic devices get smaller and microchip metal interconnects continue to shrink from the current 14 nanometer level to a 1 nanometer level, or even atomic size, a better understanding about how nanostructures behave in this extremely small regime is essential. Equally important is a better understanding of how catalysts, used in fuel cells, refining, and chemical processes can be improved.

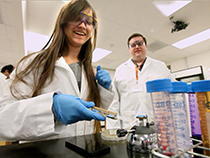

Using a similar approach to electroplating, such as used for covering cutlery with a thin layer of silver, the researchers are able to electrodeposit a single isolated platinum atom or small clusters of a few atoms onto an inert bismuth ultramicroelectrode (UME) immersed in a femtomolar chloroplatinic acid solution. The extremely low concentration of the electroplating solution allows the precise control of the plating rate at one atom every few seconds.

The deposited platinum atoms can then be immediately characterized electrochemically to estimate their size and catalytic activity via hydrogen evolution reaction. The bismuth does not evolve hydrogen, but by increasing the voltage the researchers measure an increase in the current, caused by even the presence of a single platinum atom on the bismuth surface. This current increases with the number of platinum atoms deposited, which allows the determination of their size.

Comments