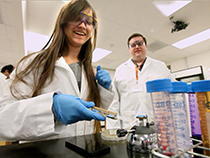

Pieces of detectors for particle colliders and neuroscience research line the shelves in the UT Austin Physics Machine Shop. The air constantly hums with the noise of advanced machines at work.

The UT Physics Machine Shop, housed in the basement of the RLM building, fabricates instruments for research and educational purposes. The shop is now a Core Facility in the College of Natural Sciences and is available to researchers in all departments of the College to fabricate their instruments. There is an hourly charge to partially offset the cost of operating the facility.

The shop's work primarily supports research in physics, but other departments are learning that the Physics Machine Shop is a valuable resource for them, too. The machine shop encompasses the main machine shop, a student machine shop, a small electronics shop, and a cryogenics shop that supplies liquid helium and gases.

Allan Schroeder began working at the machine shop 28 years ago as a welder and machinist. Schroeder now supervises the machine shop.

"I think I made a smart decision by making a career out of the physics department," Schroeder said. "Every day, students and faculty come to us with a different challenge."

Schroeder said that he enjoys the opportunity to work on research projects. One of his favorite projects was building muon detectors, which track decay particles from cosmic rays bombarding the earth's surface.

"They currently have them buried around a pyramid in Belize," Schroeder said. "They're using the muon detectors we built to map the interior of the pyramid to see if there are any hidden chambers."

The main machine shop, which handles most of the major research instrumentation, is staffed by nine full-time machinists, with a tenth overseeing the student shop. Each machinist said that they were proud of their work, but were happy to admit that they often seek each other's advice on projects.

"They all have different specialties," Schroeder said. "Some are better at making the little intricate parts, some are better at making the big chambers. That's not to say one can't do the other—they can all do anything submitted to the shop, but we all have specialties."

Herb, one of the machinists, specializes in computerized numerical control machines, commonly called CNC machines. He helps program and operate the shop's four CNC stations.

For the past two weeks, Herb has been manufacturing prototype parts for an upgrade to the ALICE detector in the Large Hadron Collider, a particle accelerator at the CERN laboratory in Geneva, Switzerland. If UT's proposal is accepted, the Physics Machine Shop will produce 42 more pieces for the ALICE detector.

"We've really reduced the time it normally takes to build these parts," Herb said.

The machine shop doesn't just build parts for advanced particle physics research, though. Any student in the College of Natural Sciences can have their designs fabricated.

To submit a project to the main machine shop, a student begins by submitting a drawing with the necessary dimensions to Schroeder for review. After the design has been reviewed, it takes about 10 business days for the project to begin, depending on the current workload for the shop.

"Often we'll work with students with absolutely no drafting background," Schroeder said. "And they'll submit amazing projects and designs, some of which I don't even know if I could design myself. We really enjoy working with students."

The student machine shop allows students to try their hand at constructing their own designs. In the student machine shop, the equipment has been modified to include features such as machine guards, emergency stop switches, and monitoring cameras. Schroeder said the student machine shop prioritizes safety above all else.

"The student shop supervisor has students go through training and he really preaches safety," Schroeder said. "I think that speaks to the safety ethos we've got here."

Schroeder said the shop's machinists enjoy the opportunity to work on diverse projects from departments across the College.

"We are happy to work with whatever people bring us," Schroeder said. "We love it when people bring us new types of challenges."

This article was written by Megan Kallus, a junior English major, and Max Parks, a fifth-year Physics and Astronomy student who will happily talk about space to anyone who will listen.

Comments 1

Love it.

Machine Shop is were the rubber meets the road in the Physics Department