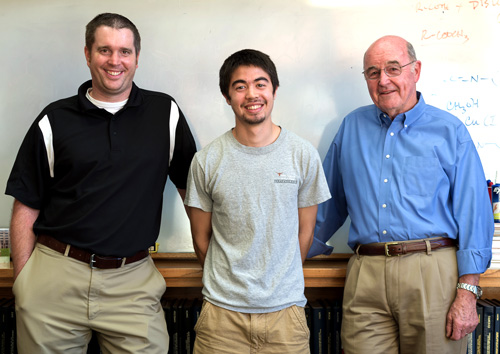

Chemistry Professor C. Grant Willson (right), Engineering Professor Chris Ellison (left) and undergraduate Leon Dean (center) co-authored a paper in Science highlighting research that could lead to increases in computer memory. Photo: Alex Wang.

Chemistry Professor C. Grant Willson (right), Engineering Professor Chris Ellison (left) and undergraduate Leon Dean (center) co-authored a paper in Science highlighting research that could lead to increases in computer memory. Photo: Alex Wang.AUSTIN, Texas — The storage capacity of hard disk drives could increase by a factor of five thanks to processes developed by chemists and engineers at The University of Texas at Austin.

The researchers’ technique, which relies on self-organizing substances known as block copolymers, was described this week in the Nov. 9 issue of the journal Science. It’s also being given a real-world test run in collaboration with HGST, one of the world’s leading innovators in disk drives.

“In the last few decades there’s been a steady, exponential increase in the amount of information that can be stored on memory devices, but things have now reached a point where we’re running up against physical limits,” said C. Grant Willson, professor of chemistry and biochemistry in the College of Natural Sciences and the Rashid Engineering Regents Chair in the Cockrell School of Engineering.

With current production methods, zeroes and ones are written as magnetic dots on a continuous metal surface. The closer together the dots are, the more information can be stored in the same area. But that tactic has been pretty much maxed out. The dots have now gotten so close together that any further increase in proximity would cause them to be affected by the magnetic fields of their neighboring dots and become unstable.

“The industry is now at about a terabit of information per square inch,” said Willson, who co-authored the paper with chemical engineering professor Christopher Ellison and a team of graduate and undergraduate students. “If we moved the dots much closer together with the current method, they would begin to flip spontaneously now and then, and the archival properties of hard disk drives would be lost. Then you’re in a world of trouble. Can you imagine if one day your bank account info just changed spontaneously?”

There’s a quirk in the physics, however. If the dots are isolated from one another, with no magnetic material between them, they can be pushed closer together without destabilization.

This is where block copolymers come in. At room temperature, coated on a disk surface, they don’t look like much. But if they’re designed in the right way, and given the right prod, they’ll self-assemble into highly regular patterns of dots or lines. If the surface onto which they’re coated already has some guideposts etched into it, the dots or lines will form into precisely the patterns needed for a hard disk drive.

This process, which is called directed self-assembly (DSA), was pioneered by engineers at the University of Wisconsin and the Massachusetts Institute of Technology.

When Willson, Ellison and their students began working with directed self-assembly, the best anyone in the field had done was to get the dots small enough to double the storage density of disk drives. The challenge has been to shrink the dots further and to find processing methods that are compatible with high-throughput production.

The team has made great progress on a number of fronts. They’ve synthesized block copolymers that self-assemble into the smallest dots in the world. In some cases they form into the right, tight patterns in less than a minute, which is also a record.

“I am kind of amazed that our students have been able to do what they’ve done,” said Willson. “When we started, for instance, I was hoping that we could get the processing time under 48 hours. We’re now down to about 30 seconds. I’m not even sure how it is possible to do it that fast. It doesn’t seem reasonable, but once in a while you get lucky.”

Most significantly, the team has designed a special top coat that goes over the block copolymers while they are self-assembling.

“I’ve been fortunate enough to be involved in the experimental work of the top coat project from its inception all the way to our final results,” said Leon Dean, a senior chemical engineering major and one of the authors on the Science paper. “We’ve had to develop an innovative spin-on top coat for neutralizing the surface energy at the top interface of a block copolymer film.”

This top coat allows the polymers to achieve the right orientation relative to the plane of the surface simply by heating.

“The patterns of super small dots can now self-assemble in vertical or perpendicular patterns at smaller dimensions than ever before,” said Thomas Albrecht, manager of patterned media technology at HGST. “That makes them easier to etch into the surface of a master plate for nanoimprinting, which is exactly what we need to make patterned media for higher capacity disk drives.”

Willson, Ellison and their students are currently working with HGST to see whether these advances can be adapted to their products and integrated into a mainstream manufacturing process.

Other industry collaborators are Nissan Chemical Company, which partially funded the research, and Molecular Imprints, an Austin-based company co-founded by Willson that is a pioneer in nanoimprint lithography.

For more information contact: Daniel Oppenheimer, College of Natural Sciences, 512-745-3353;

C. Grant Willson, Department of Chemistry and Biochemistry, (512) 471-4342, willson@che.utexas.edu

Comments