Algae has gained significant attention as a feedstock for biofuels and as an alternative to other petroleum-based products because of its potential for high yields, high productivity and scalability.

The high productivity of the facility can be accomplished with a small footprint, thanks to unique vertical, closed-loop algal growth chambers, called vertical growth modules (VGM). The VGM’s have been developed by AlgEternal in conjunction with Georg Fischer, a multi-billion dollar piping systems company and exclusive supplier for the project.AUSTIN, Texas — The University of Texas at Austin, in partnership with AlgEternal Technologies and Georg Fischer Piping Systems, has officially opened one of the largest of-its-kind algae growth demonstration facilities for biofuels in the country.

The high productivity of the facility can be accomplished with a small footprint, thanks to unique vertical, closed-loop algal growth chambers, called vertical growth modules (VGM). The VGM’s have been developed by AlgEternal in conjunction with Georg Fischer, a multi-billion dollar piping systems company and exclusive supplier for the project.AUSTIN, Texas — The University of Texas at Austin, in partnership with AlgEternal Technologies and Georg Fischer Piping Systems, has officially opened one of the largest of-its-kind algae growth demonstration facilities for biofuels in the country.

Algae production has gained significant attention as a feedstock for biofuels and as an alternative to other petroleum-based products because of its potential for high yields, high productivity and scalability.

“The vast commercial potential of algae as a renewable resource has barely been tapped,” said Jerry Brand, the Jack S. Josey Professor in Energy Studies and director of the UTEX Culture Collection of Algae in the College of Natural Sciences. “At The University of Texas at Austin, we have a unique combination of intellectual experience and capability, research and development facilities, and a huge library of living algae that together can exploit this potential. The new algae culturing and harvesting facility designed and built by AlgEternal is an excellent synergist to our existing capability that will accelerate commercialization.”

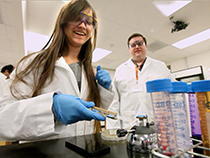

It will demonstrate the commercial potential of two of AlgEternal’s unique technologies. They will produce algae that will be used by researchers at the university’s Center for Electromechanics (CEM) to demonstrate their proprietary technology for extracting oil from algae. The UTEX Culture Collection of Algae will serve as a source for strains of algae.

The facility has a 16,000-gallon capacity and is capable of producing up to 5,000 gallons of algae each day for biofuel research.

This high productivity can be accomplished with a small footprint, thanks to unique vertical, closed-loop algal growth chambers, called vertical growth modules (VGM). The VGM’s have been developed in conjunction with Georg Fischer, a multi-billion dollar piping systems company and exclusive supplier for the project.

The facility’s VGMs are shaded by a light refraction canopy that diffuses the sunlight reaching each VGM, thereby promoting prolific growth of the algae. The system utilizes natural solar power, which contributes to its overall sustainability.

“The future commercialization of advanced algae biofuels is dependent upon reducing the cost of growth another ten-fold,” said Robert Hebner, director of the CEM and research professor in the Cockrell School of Engineering. “Science and commercial progress are symbiotic. We’ve organized a highly competent team addressing key science and engineering challenges and it is essential that we collaborate with companies like AlgEternal in order to understand biofuel production from the process level to accelerate research in this emerging industry. ”

“Our company began growing algae at a pilot scale to ensure laboratory research would translate to real world scenarios,” said Rob Eissler, CEO of AlgEternal Technologies. “We’re using an organic source of energy to reduce overall costs associated with mass production and are utilizing proven farming techniques to manage cultures rather than try to control them.”

Current methods for growing algae primarily rely on open algal ponds. The VGM’s grow about 16-and-a-half times more algae per acre than open pond methods. The system has been carefully engineered to reduce water consumption and overall energy usage to remain economically competitive with open pond methods.

The facility is located at the J.J. Pickle Research Campus in North Austin.

The Center for Electromechanics (CEM)

The CEM works with a world-class team of researchers from multiple engineering and science department across The University of Texas at Austin to pursue and exploit fundamental science to produce innovation needed to achieve cost-effective algae extraction and processing solutions. The university’s algae processing team has developed a proprietary algae extraction technology that will be used to extract oil from the algae feedstock for conversion to biofuel.

UTEX Culture Collection of Algae

The UTEX Culture Collection of Algae is one of the world’s largest collections with more than 3,000 strains of algae. It’s a prime source for selecting strains of algae for biofuel potential. The collection, directed by Dr. Jerry Brand, is part of the College of Natural Sciences’ research efforts directed toward producing clean fuels.

AlgEternal Technologies

AlgEternal Technologies has developed a proprietary vertical growth system that combines innovative, closed-loop technology with light refraction techniques to produce a commercially viable quantity of algae that can be used for production of advanced algae biofuels and other algae byproducts. The vertical placement of the technology is critical in reducing land usage and the overall production footprint, and the closed system eliminates contamination issues typically associated with “open” growth methods. AlgEternal’s system is engineered to reduce water consumption and energy usage typically associated with algae growth, significantly reducing production costs.

Georg Fischer

GF Piping Systems is dedicated to designing, manufacturing, and marketing piping systems for the safe and secure conveyance of liquids and gases. As a leading supplier of plastic piping systems, GF contributes to the research and development of energy-efficient uses of raw materials and resources. GF is committed to making a contribution in the areas of climate protection and clean drinking water, both in its processes and in the products it manufactures.

For more information, contact: Lee Clippard, College of Natural Sciences, 512-232-0675; Cari Vincent, AlgEternal Technologies, 215-802-0709

Comments 1

To learn about the fast-track commercialization of the algae production industry you may want to check out the National Algae Association, the trade association.